Pattern Transfer Page 3

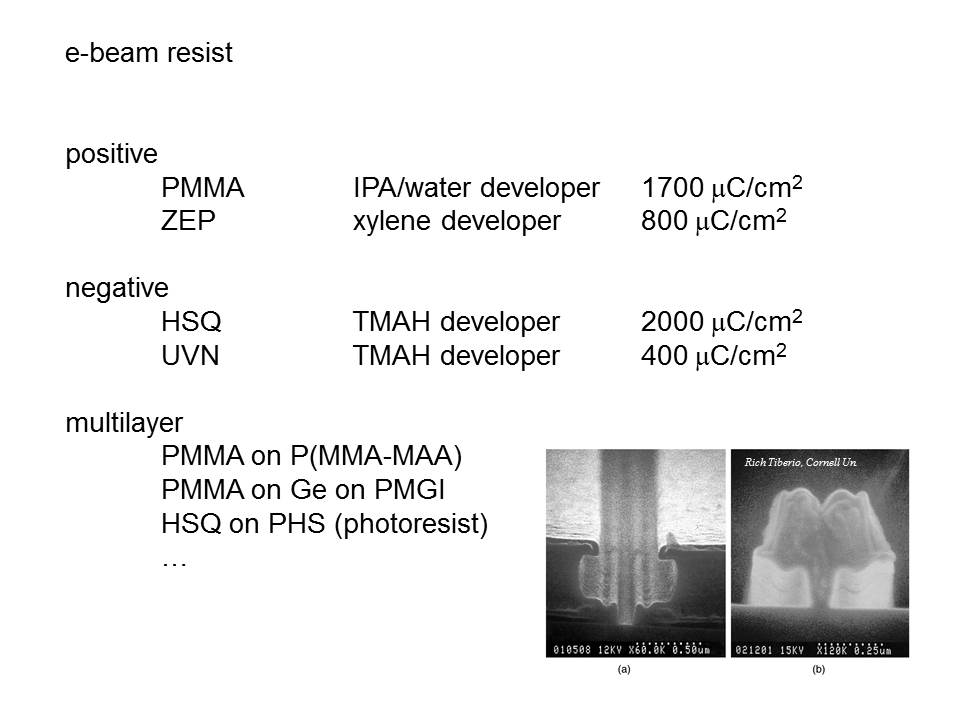

In electron-beam lithography you have a limited selection of resists. The positive resists PMMA and ZEP are polymers that are broken up by electron irradiation. After exposure, the smaller bits dissolve faster in the “developer”. This is a very simple contrast mechanism; there isn’t any complex chemistry as you find in photoresist. (There are more complicated chemically amplified e-beam resists, but they are way too fussy and not worth the effort.)

The negative resist HSQ contains monomers which are crosslinked by the electron beam. The unexposed regions wash away in developer. UVN and ma-N are two other negative resists, but are far more difficult to use. For no apparent reason, ma-N negative resist has become more popular than UVN. Both have at best 50 nm resolution, and both use chemical amplification to induce crosslinking. HSQ has the best resolution of any e-beam resist, in the range below 8 nm.

Multilayer resist systems usually involve PMMA and the copolymer P(MMA-MAA). The copolymer is more sensitive to electron exposure, and so we typically put a layer of copolymer UNDER a layer of PMMA to form a large undercut resist profile. A large undercut is handy for doing metal liftoff.

YINQE provides PMMA, ZEP, HSQ and copolymer. We do not stock UVN and ma-N, and so if you want to use one of these then you’re on your own. ZEP and HSQ are quite expensive, and so we have to charge extra for those.