E-beam parameters

E-beam parameters Page 2

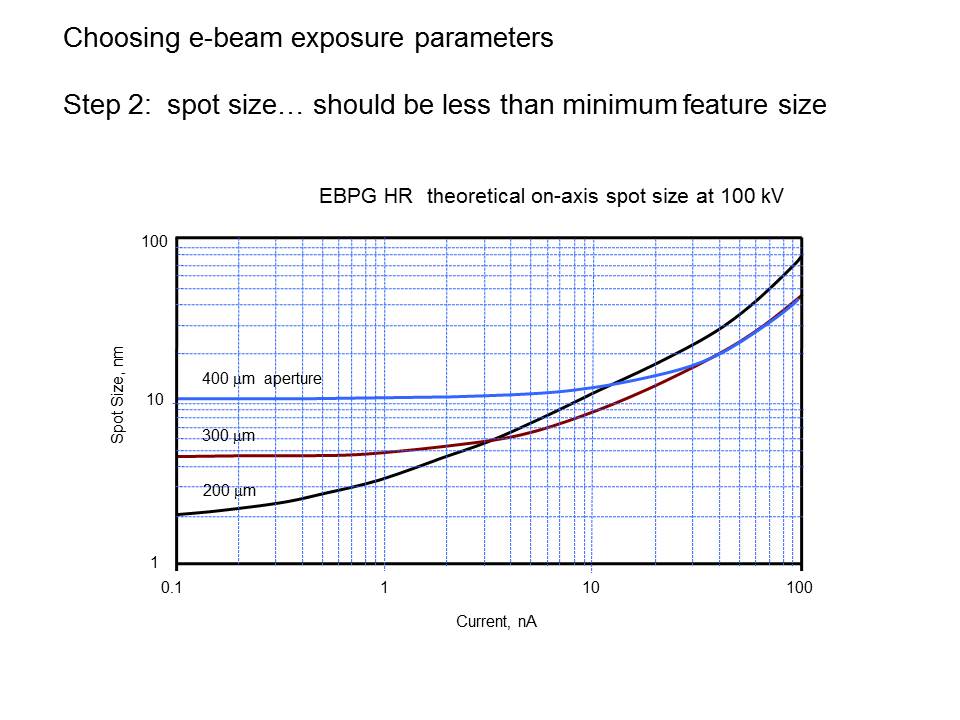

For example, if you want 20nm wide lines you should use a spot size no larger than about 5nm. According to this plot, you could choose the 200um aperture at 3 nA, or you could choose the 300um aperture at 1 nA. So the 200 um aperture is the better choice. If you set up an exposure job that calls for different currents and different apertures, the system will switch to them automatically. Yes: it will even switch apertures automatically!

E-beam parameters Page 3

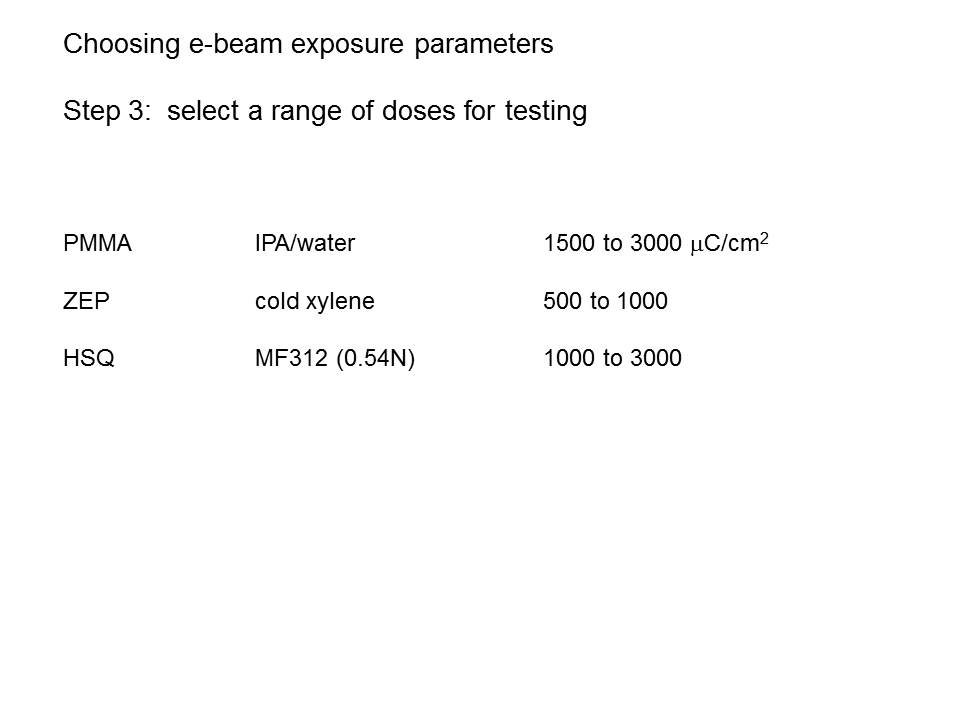

Your first run should always be a dose test. Choose a range of doses that goes from too low to too high. Then expose your pattern (or part of it) a number of times using different doses. The best dose will depend on the pattern, the substrate, the developer and to some extent on the pattern transfer technique. It’s not like using a paper printer; some testing and tweaking is always required.

E-beam parameters Page 4

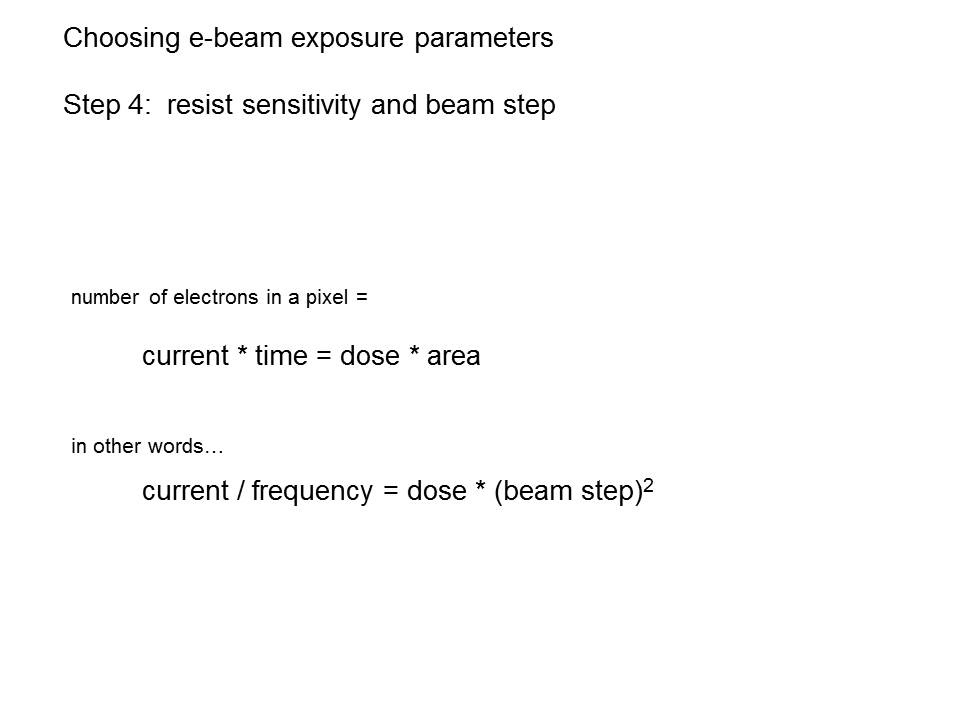

What do we mean by “area”? If you plug in the area of your pattern, then the calculated time will be the total exposure time. If you plug in the area for one pixel then the time will be the “dwell time” for one pixel. The dwell time is the inverse of the clock frequency. The highest clock frequency is 50 MHz. This constrains the exposure current and the beam stepping distance.

E-beam parameters Page 5

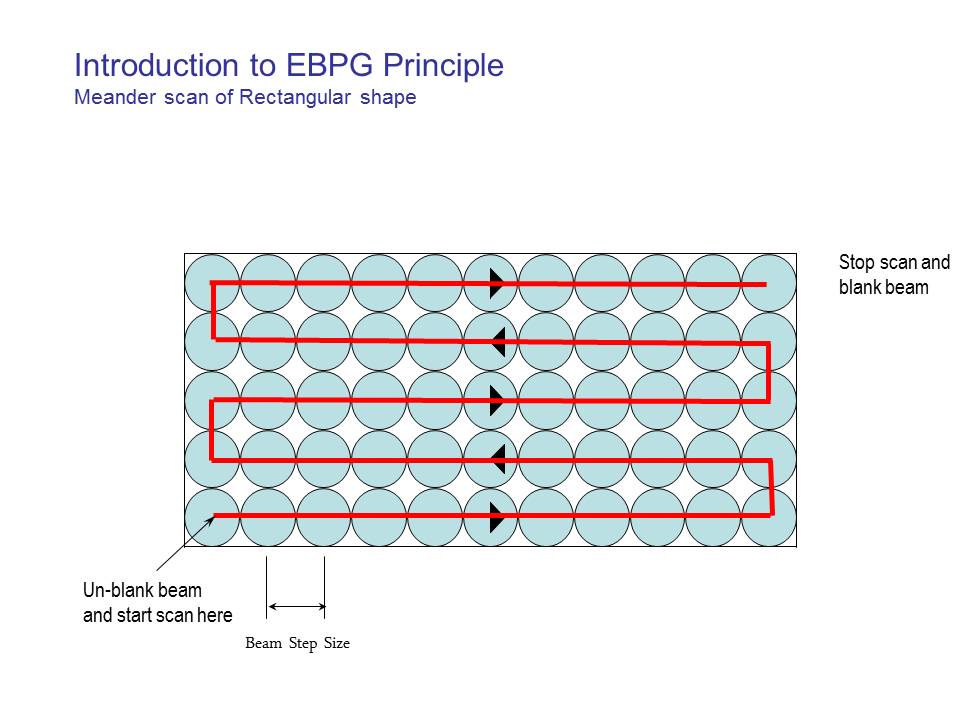

The beam step size is the effective pixel size, even if the beam spot is larger or smaller than this number. Use the beam step size when calculating the dose delivered to one pixel. The beam step size is always a multiple of the least significant bit of the deflector DAC. If you don’t know what a digital-to-analog converter (DAC) is, then look it up. One bit on the EBPG’s DAC deflects the beam 1 nm. We have a 20 bit DAC, so… WHAT IS THE MAXIMUM DEFLECTION?

E-beam parameters Page 6

E-beam parameters Page 7

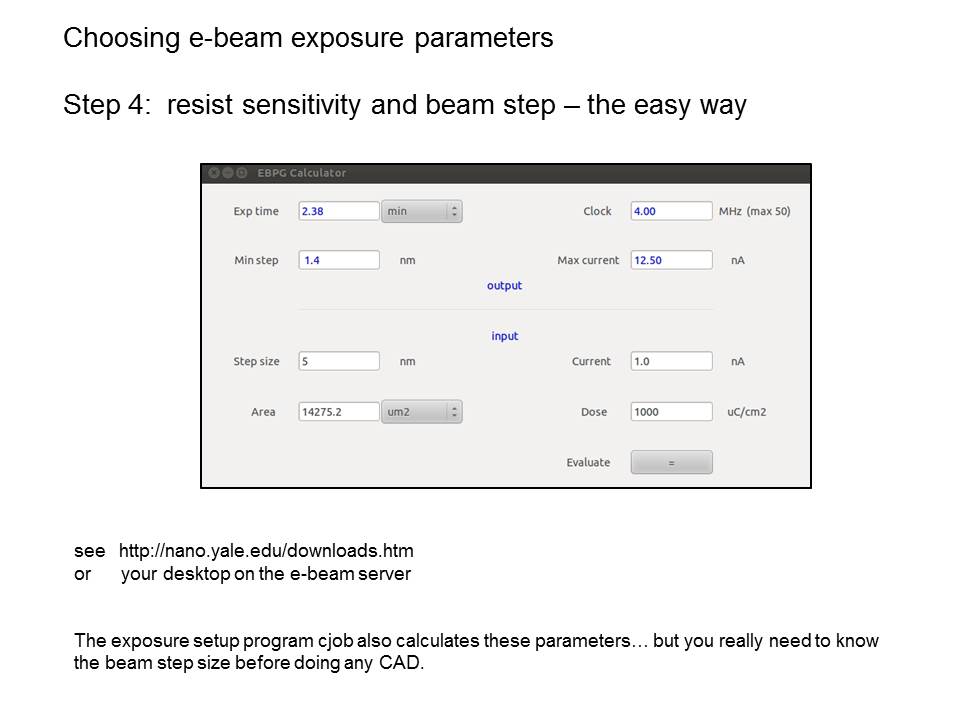

That’s right: you can use this handy dandy parameter calculator. The calculator can be found on the e-beam server desktop. Use the parameter calculator to answer THESE QUESTIONS.